EMC (Electromagnetic Compatibility) Testing refers to the process of confirming a fair / acceptable level of functionality/performance of electrical / electronic devices in the given ambient electromagnetic environment/region. Let's define EMC testing, why it's important, and what are its types.

What Is EMC And Why Is It Important?

EMC stands for Electromagnetic Compatibility, and it refers to a circuit that has been designed to avoid being disrupted by shielding.

Electromagnetic compatibility (EMC) testing is an important aspect of the design process for any device. Because EMC certification is a requirement before your device can be sold, it's critical that you get this aspect of your design correct.

Despite its necessity, emissions testing is sometimes postponed until late in the design life cycle of a product. As a result, the chance of project delays and cost overruns close to your planned launch rises — just when you don't need this kind of stress.

EMC testing reduces the chance that your device's radiated or conducted emissions will interfere with other electronic devices in its area. EMC testing shield box is also in place to ensure that your electronic device will continue to function normally in the presence of other electromagnetic emissions.

So now that we know what EMC is and how it works, let us take a look at the concepts of EMC and RF Testing.

Understanding The Concepts of EMC and RF Testing

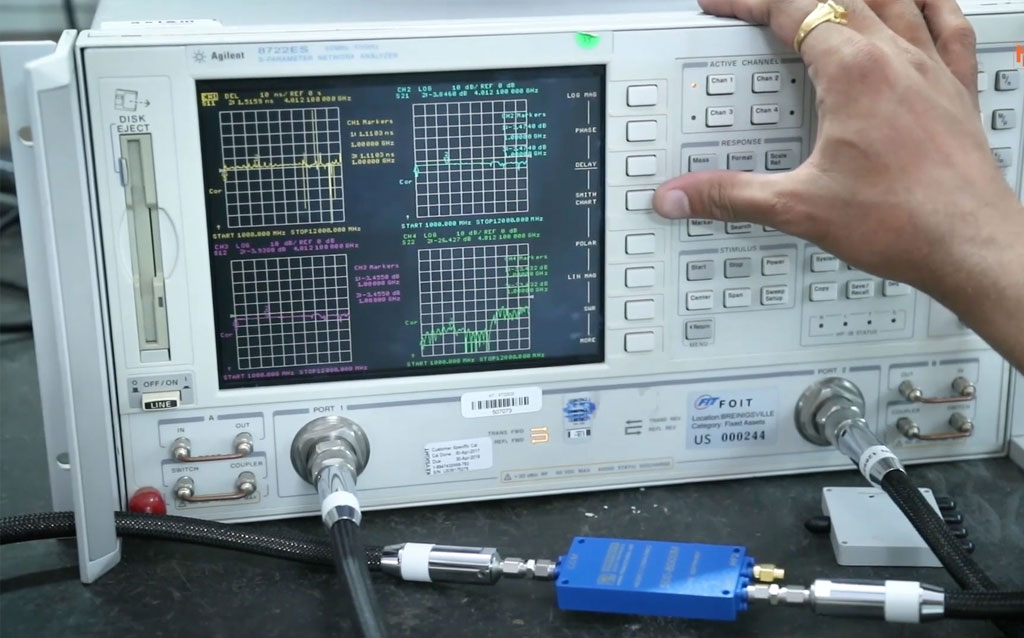

Electromagnetic compatibility (EMC) and radio frequency (RF) testing, which includes Over The Air Testing (OTA) and Specific Absorption Rate (SAR) testing, examines a device's ability to operate safely and effectively when it is in close proximity to other electronic devices or when electromagnetic emissions are present.

The radiofrequency (RF) energy that a product emits is known as electromagnetic emissions. Conducted and radiated are the two main categories.

Cables and conductors in many electronic types of equipment do not operate effectively as antennas at frequencies up to 30 MHz. As a result, radiated emissions aren't a big concern at these frequencies. These cables and conductors, on the other hand, can conduct RF energy through shared power sources or loads, causing conducted emissions to interfere with other electronics. RF Testing Equipment are versatile and efficient enough.

Conducted emissions are normally no longer an issue beyond 30 MHz, however, conductors and cables become antennas with the potential to transmit RF energy, causing interference with other equipment.

Major Segments of EMC Testing

Basic Test Methods of EMC Testing are:

1) Conducted Testing

The portion of electromagnetic energy created by a product that is conducted onto the power supply cord is measured in conducted emissions testing. The goal of the test is to ensure that the emissions meet the limitations set forth in relevant EMC regulations, which typically range from 150 kHz to 30 MHz.

2) Radiated Testing

Radiated emissions testing determines the strength of the electromagnetic field produced by the electrical product. The currents and switching voltages in any Analog/Digital circuit produce these emissions.

Reference Product EMC Compliance Standards where Shield Boxes can be used as pre-certification test setups are CISPR11 , CISPR22 , EN55011 , EN55022 , CCI (Class A/B) , FCC Part15

Comments

Add CommentNo Comments Available